Pressure Enthalpy Chart for R22 Made Easy

Understanding the P-H Diagram

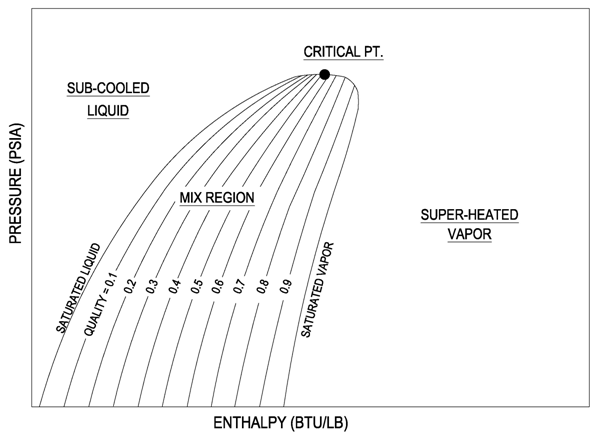

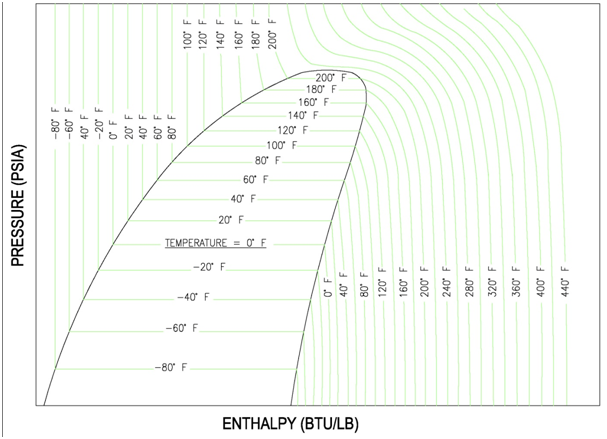

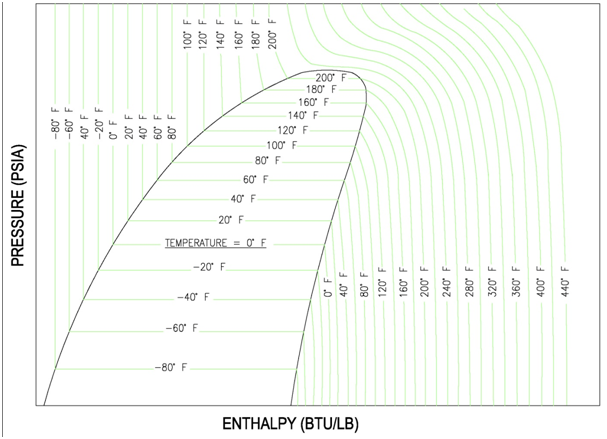

On the P-H diagram, pressure level is indicated on the y-axis and enthalpy is indicated on the x-axis. Typically enthalpy is in units of Btu/lb and pressure is in units of pounds per square inch (psi). The upside down U figure shown on the diagram designates the points at which the refrigerant changes phase. The left vertical bend indicates the saturated liquid curve and the correct vertical curve indicates the saturated vapor curve. The region in between the ii curves describe refrigerant states that contain a mixture of both liquid and vapor. The locations to the left of the saturated liquid curve indicate that the refrigerant is in liquid form and locations to the right of the saturated vapor curve signal that the refrigerant is in vapor form. The indicate at which the two curves encounter is called the critical point. The importance of this bespeak is that at whatsoever signal higher up, no additional pressure level will change the vapor into a liquid. A simplified pressure level-enthalpy diagram is shown below, describing this data.

The curves suspension up the diagram into three regions (1) Liquid, (ii) Vapor and (three) Mix.

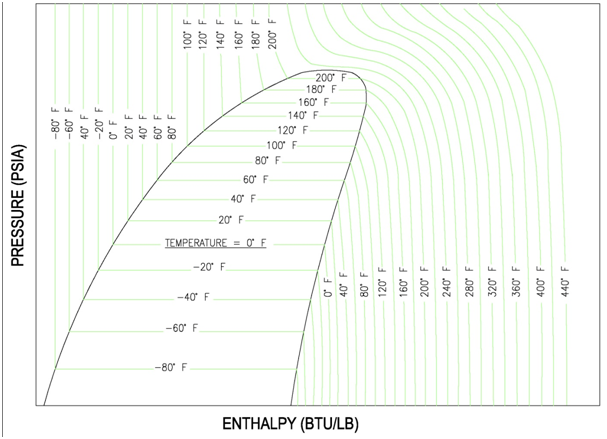

(1) Liquid Region: The liquid region is besides known equally the sub-cooled region. In this region there are vertical temperature lines, which increase every bit enthalpy is increased. Figure eight is a simplified P-H diagram illustrating the constant temperature lines.

(2) Vapor Region: The vapor region is also known equally the super heated region. In this region at that place are vertical temperature lines, which increment as enthalpy is increased. Refer to Effigy viii. There are also lines of constant entropy, which are too important. Entropy is the measure out of the corporeality of disorder in the organisation.

(iii) Liquid-Vapor Mix Region: In this region, the P-H diagram shows horizontal temperature lines, which point abiding temperature. The mix region is the phase change region, where whatsoever addition of enthalpy will cause boosted liquid to vaporize instead of raising the temperature. Figure 8 illustrates the horizontal temperature lines in the mix region. There are also upward sloping curves which betoken quality. Quality is a measure of the ratio of vapor mass to total mass. For example quality of 0.one or x%, which is located near the saturated liquid line, describes points that accept 10% vapor by mass. The 0.9 or xc% line, which is located near the saturated vapor line, describes points that accept 90% vapor by mass. The previous figure, Figure 7, indicates the quality lines.

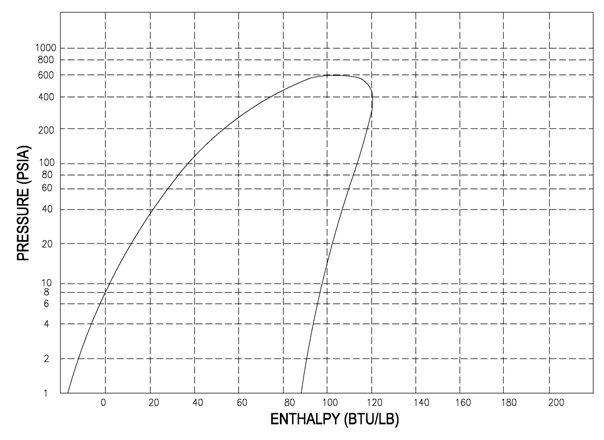

The x-y axes of the P-H diagram are the pressure lines running from left to right. The enthalpy lines are the vertical lines. The skeletal graph shown below shows the pressure level-enthalpy lines.

Refrigeration Bicycle

One of the almost of import skills needed for the professional engineer in the HVAC and Refrigeration field is navigating the refrigeration bicycle on a pressure-enthalpy diagram. The following sections volition show each specific part of the refrigeration cycle on the pressure-enthalpy diagram and it will also highlight the important points and calculations needed.

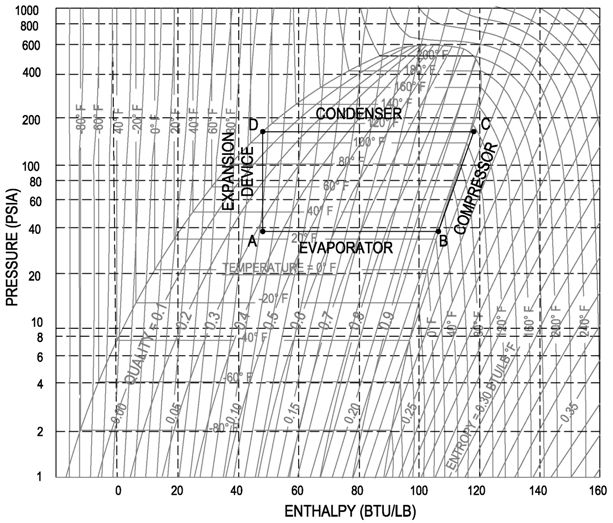

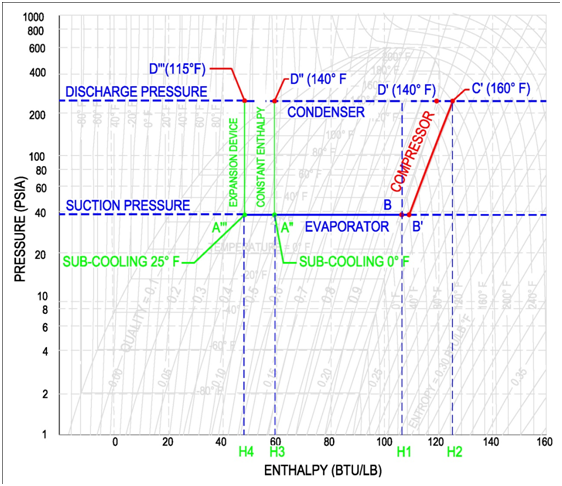

Throughout this caption the refrigerant R-134a is used as an instance. It is recommended that the engineer go a copy of the P-H diagram for R-134a and the other mutual refrigerants. These diagrams tin be institute in the ASHRAE Fundamentals book. A sample R-134a diagram is shown beneath, with a sample refrigeration cycle, identifying (Step 1) Evaporator, (Step 2) Compressor, (Step 3) Condenser and (Step 4) Expansion Device.

STEP i: EVAPORATOR

The refrigerant entering the evaporator is a cold, partial liquid-vapor mixture. The operating pressure and temperature of the evaporator is called the suction pressure and suction temperature. The suction line is the piping that routes refrigerant gas from the evaporator to the compressor. It is important to annotation that in the mix region, the pressure and temperature are dependent variables.

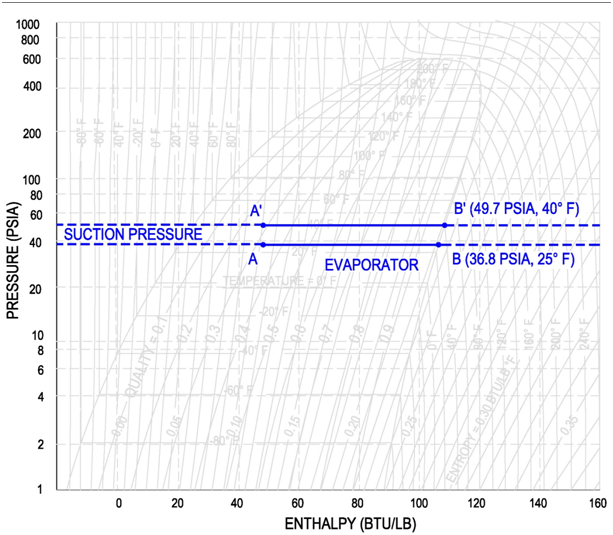

For case, if a compressor operates at a suction pressure of 36.8 psia, then the respective evaporator pressure is 36.8 psia and the respective evaporator temperature is 25 °F, come across below figure for points A and B (Values are for Refrigerant R-134a). If the compressor operates at a suction force per unit area of 49.7 psia, then the respective evaporator pressure is besides 49.7 psia and the evaporator temperature is twoscore °F. See below figure for points A' and B'(Values are for Refrigerant R-134a).

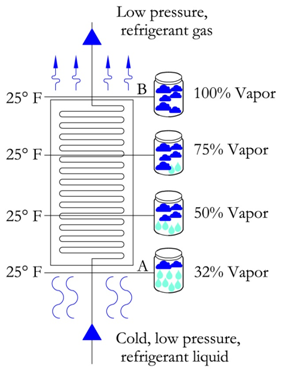

The evaporator moves the refrigerant from betoken A (partial liquid-vapor mixture) to point B, a fully saturated vapor refrigerant. As the evaporator transfers oestrus to the refrigerant, in that location is no gain in temperature, since all the heat is used to convert the remaining liquid to a gas. In an platonic evaporator, in that location is just enough heat transfer to convert all the liquid to gas and nothing more. Thus, the output of an ideal evaporator is 100% vapor at the same entering temperature, refer to effigy below. In this figure, we see that as the refrigerant moves through the evaporator, the temperature remains the same and the percentage of vapor increases, until it reaches saturation at 100%.

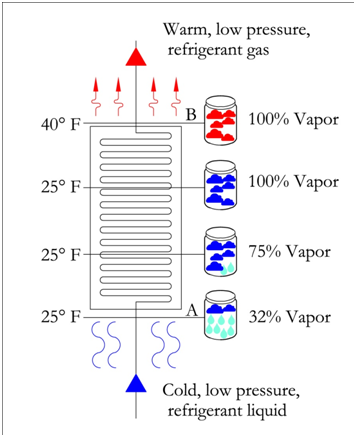

Besides introduced in the figure above is the term superheat. If additional heat were to be added to the 100% vapor refrigerant, then the estrus would be used to increase the temperature and it is this increment in temperature that is called superheat.

In the figure below, an evaporator with 15 °F superheat is shown. The refrigerant reaches 100% vapor prior to leaving the evaporator. All the boosted heat from this signal is used to increment the temperature of the refrigerant until it reaches a temperature of forty °F. This refrigerant has a superheat of 15 °F considering the terminal temperature is 15 degrees passed the saturation temperature of 25 °F. Information technology is important to note that the pressure remains constant throughout the evaporator.

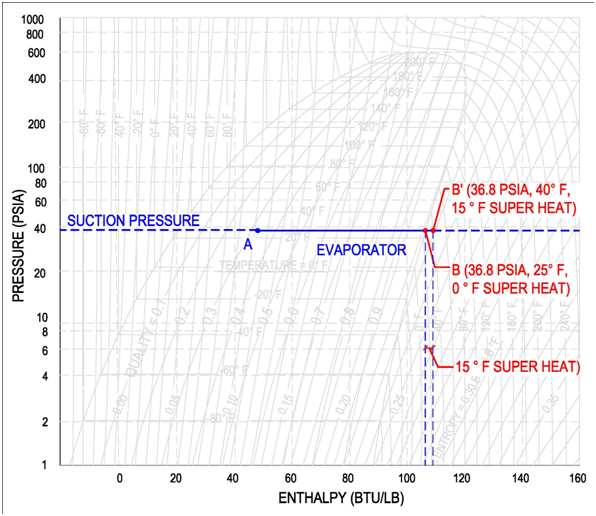

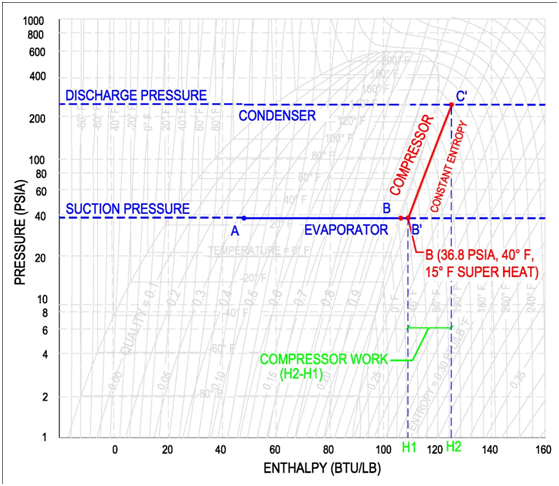

On the pressure-enthalpy diagram superheat is shown as horizontal movement along the suction pressure line passed the 100% vapor curve. The figure on the post-obit folio shows the divergence between 0 °F and 15 °F superheat. Signal B is the 100% vapor point at a constant evaporator/suction pressure of 36.viii psia and a temperature of 25 °F. Point B' results from boosted heat/enthalpy added to the refrigerant. The refrigerant moves from point B to signal B', where the resulting temperature is forty °F.

STEP 2: COMPRESSOR

The compressor is characterized by the refrigerant suction and discharge conditions. Horizontal lines are fatigued across the refrigerant's pressure enthalpy diagram for the suction and belch pressures. Then the incoming temperature of the compressor, as adamant past the leaving temperature of the evaporator, is used as the starting indicate of the compressor, as shown by point B' on the figure below. The compressor and then increases the pressure of the refrigerant upward to the discharge pressure. Compression occurs at constant entropy, besides known every bit isentropic pinch. Therefore the intersection of the constant entropy line and the discharge pressure line volition place the final condition of the refrigerant gas leaving the compressor, as shown by betoken C' in the figure below.

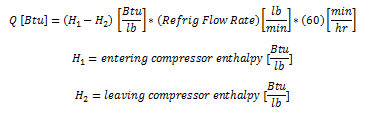

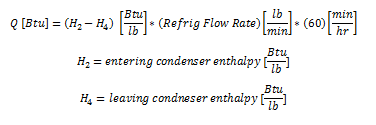

A common skill, that is required of a professional engineer, is to make up one's mind the work done by the compressor. This work is shown in the figure above as the difference between the compressor inbound enthalpy (H1) and the leaving enthalpy (H2). The equation to determine the work of the compressor is shown below. This equation multiples the refrigeration catamenia rate by the change in enthalpy between the discharge and suction conditions.

The 10-y axes of the P-H diagram are the pressure level lines running from left to right. The enthalpy lines are the vertical lines. The skeletal graph shown below shows the pressure-enthalpy lines.

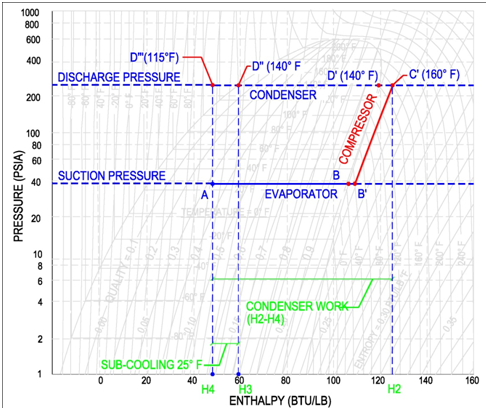

STEP 3: CONDENSER

The refrigerant entering the condenser is now a hot, high pressure refrigerant gas. The condenser is shown on the pressure-enthalpy diagram equally a horizontal line. This horizontal line is a line of constant pressure, respective to the discharge pressure of the compressor. The condenser proceeds from right to left in the post-obit iii steps:

(1) The superheated gas cools downwards to saturation temperature [C' 160 °F to D' 140 °F]. Cooling takes place every bit heat flows from the hot refrigerant gas to the condenser cooling medium.

(two) Next, the 100% saturated vapor at D' is converted to 100% saturated liquid at D''. Rut is lost to the condenser cooling medium as the vapor is condensed to a liquid.

(three) Finally, the 100% saturated liquid is sub-cooled from D'' to D'''[140 °F to 115 °F]. In an ideal condenser, no sub-cooling occurs. Once the refrigerant is a fully saturated liquid, whatsoever boosted oestrus loss results in a subtract in temperature. This cooling of the saturated liquid is referred to as sub-cooling. In this example, the refrigerant has gone through 25 °F of sub-cooling and resulted in a sub-cooled temperature of 115 °F.

A common question is to determine the heat expelled by the condenser, which is shown in the figure above as the deviation between the condenser inbound condition (H2) and the leaving condition (H4). The equation to determine the net condenser result is shown below. This equation multiples the refrigeration period rate past the change in enthalpy betwixt the entrance and exit of the condenser.

The x-y axes of the P-H diagram are the pressure lines running from left to correct. The enthalpy lines are the vertical lines. The skeletal graph shown below shows the pressure-enthalpy lines.

STEP 4: EXPANSION DEVICE

The expansion device is the analogue of the compressor. Similarly, the expansion device is characterized by the suction and discharge pressures. Horizontal lines are once again drawn on the refrigerant's pressure-enthalpy diagram. The input condition of the expansion device is adamant by the condenser output weather condition.

In that location are two entering atmospheric condition to the expansion device shown on the following diagram. The first situation has 0 °F of sub-cooling [D''] and the 2d situation has fifteen °F of sub-cooling [D'''].

The expansion device expands the high pressure refrigerant gas adiabatically to a low force per unit area liquid-vapor refrigerant mixture. Adiabatic expansion indicates that at that place is no modify in enthalpy and is characterized by a downward vertical line as shown on the below graph.

Note on the graph below equally the refrigerant moves from betoken D to signal A, the refrigerant moves from the liquid phase of the graph to the vapor-liquid mixture region. The amount of gas that is formed during this expansion is called wink gas.

Source: https://www.engproguides.com/pressure-enthalpy-diagram.html

0 Response to "Pressure Enthalpy Chart for R22 Made Easy"

Post a Comment